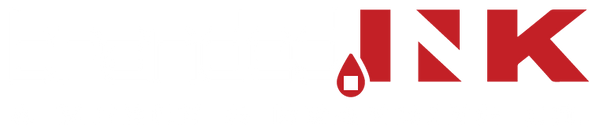

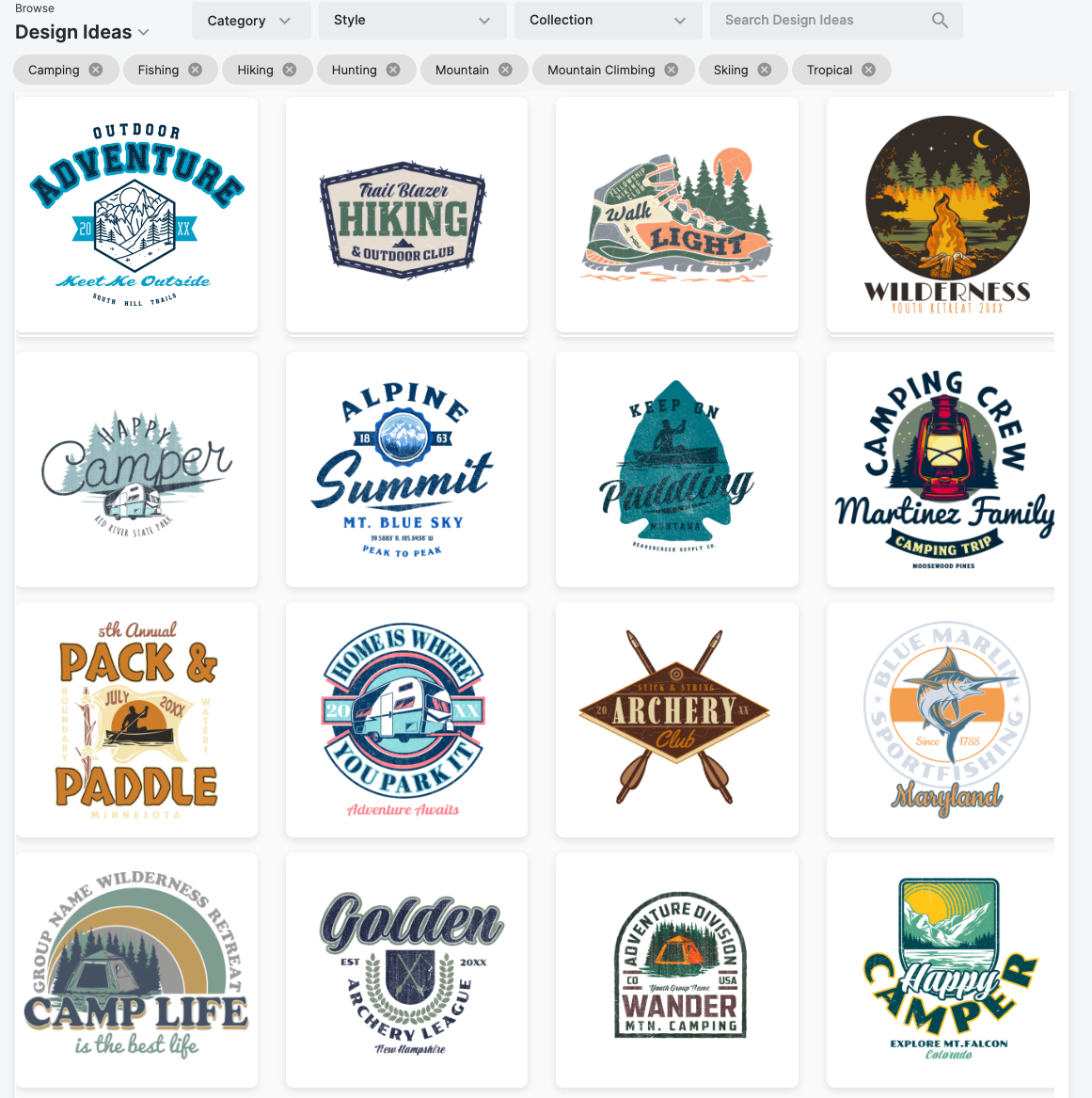

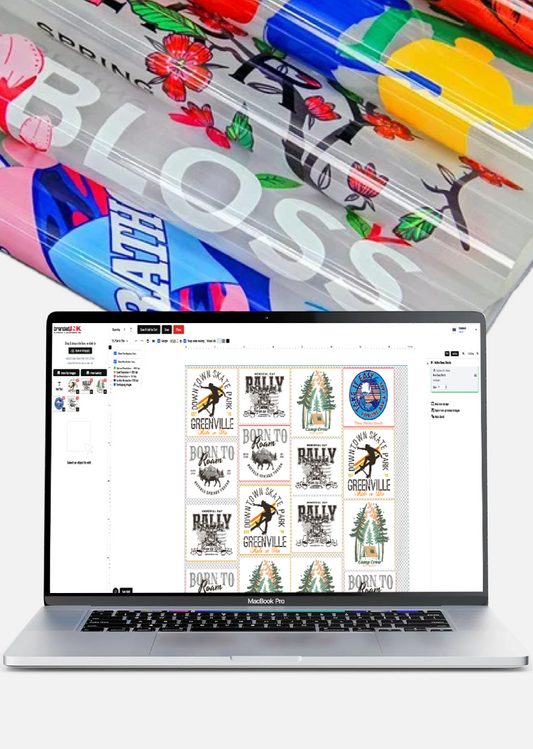

Ultra Color GFX (Lets call it GFX for the rest of this). This is our version of Direct To Garment printing on steroids but with many advantages over the typical DTG printing method.

This revolutionary process transfers prints onto fabric or other substrates using a heat-press mechanism. Unlike the DTG method, which only works on cotton fabrics, our GFX method can work on all shades of colors of cottons, poly blends, synthetics or even silk without any trouble. This process also allows us to print extra prints to save for future applications for extremely quick turn arounds and consistency.

This process has only been around for a few years but we had to be sure that the technology and reliability of the process and the machines would improve to a level that we would be confident and proud to add it to our services. That time has now arrived.

Up until now all machines were being manufactured in China with very mixed results. The printing was stellar but the same thing could not be said about the reliability of the equipment. We finally found an extremely high quality proven Japanese machine that would revolutionize the industry and were the first ones in the country to have access to that machine. We have been fortunate enough to be brokering out jobs for a long time to test the process and capabilities in order to make this leap

WHAT MAKES ULTRA COLOR SO SPECIAL?

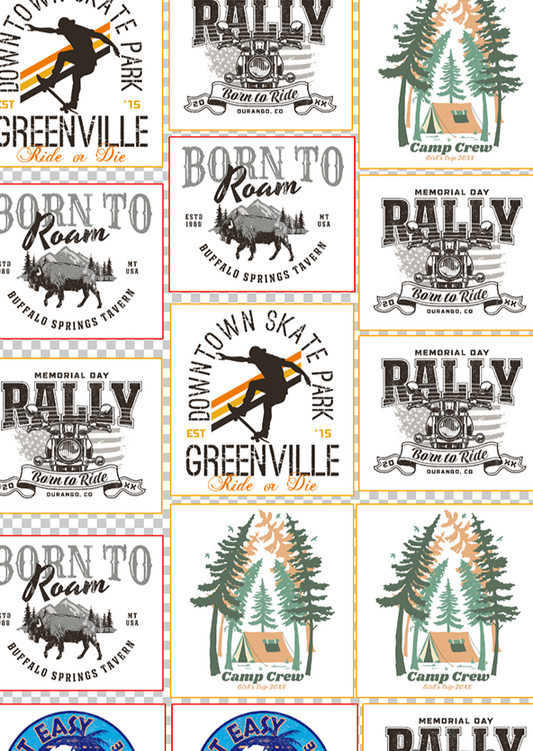

With traditional screen printing the color separation, set up times and number of colors involved made printing complex and/or photographic imagery on darks very cost prohibitive especially with small low quantity runs. Rush charges made quick turns for small runs very expensive. GFX makes simulated process prints WITH a quick turn possible and affordable because the art file is printed directly onto a polyester carrier sheet then transferred to the apparel item being decorated. We can print on:

- T-Shirts

- Hoodies

- Sweat Pants

- Hats Bags

- and more!

IMPORTANT THINGS TO KNOW ABOUT ULTRA COLOR GFX PRINTING

Although GFX and even Direct To Garment printing is just as good – perhaps more detailed – than screen print, each medium has a unique quality. For this reason, digital prints should never be used as pre-production samples no matter what the time and cost restraints are.

To best preserve the colors in your design, we recommend washing the garments inside out in cold water.

PROS AND CONS

PROS:

- Quick turn arounds

- Low quantity printing is no problem. Need just one? We got you.

- Vector artwork not required. All that’s needed is a higher quality PNG, TIFF, JPG that can be saved on a clear background.

- Can be applied to many types of materials. So far it’s been hard to find a type that this method does not apply too. Recommend staying away from topically coated materials.

- When compared to vinyl graphics heat press, GFX prints can produces prints with fades on edges without the hard lines.

- Produced high color jobs without all the screens and setups that’s required for high color screen printing

- Brighter and more solid printing as compared to DTG

CONS:

- Although faster than DTG printing its still not as fast as screen printing. Screen printing speeds are hard to beat.

- With larger solid prints it can have a more stiff print as compared to DTG and Screen Printing. Having open ares where the shirt is showing through the design, mitigates this. DTG has a more vintage soft feel so keep this in mind when deciding.

- Inks are more solid and vibrant so achieving a vintage see thorough looks is not as easy unless filters are used. DTG gives a better vintage result

When to choose direct-to-film printing

GFX technology will be better for your business if you want to sell items made with polyester, nylon, fleece, or other synthetic material. Printing on other items like bags and hats is also possible, giving you more product options.

This technique is worth trying out if your designs are detailed and colorful and it’s important that your art has the best quality when printed. GFX prints always come out vivid and sharp. They are also durable and long-lasting.

However, if you want to print a large design, let’s say a photo, this printing technique might be a bad choice. That’s because GFX prints are not breathable, which means that printing a large design makes the garment less comfortable for long wear.

Not sold on GFX prints? You can always order one for yourself in both GFX and DTG and compare the same design fulfilled with the different techniques.

Do GFX prints last longer than DTG?

GFX prints usually may last longer than DTG because of the print’s elasticity. If you wash and iron GFX-printed garments inside out and avoid washing them in hot water, the design will look new even after many washes.

Is GFX printing worth it?

Yes, GFX printing is worth it! GFX prints are vivid, detailed, and durable. You can print photos, fine art, graphics, gradients, and more. GFX printing suits many fabrics like polyester, cotton, fleece, nylon, etc.

How long does a GFX print last?

GFX prints are long-lasting and don’t fade, crack or peel even after many washes. To take good care of your GFX prints:

- Follow the garment’s care instructions

- Wash and iron printed garments inside out

- Avoid washing them in very hot water as the design may develop small cracks

Which is better—screen printing or GTX printing?

Screen printing is better than GFX printing if you need to make bulk orders and if your designs are simple and contain just one or a couple of colors. DTF printing is better than screen printing if your designs have many colors or if you want to print photos and gradients. GFX printing is also better for on-demand production, as you can print just one item.

Do GFX printing transfers crack?

GFX printing transfers won’t crack, fade, or peel even after many washes. To ensure your GFX prints last a long time, wash and iron the garments inside out, and avoid washing them in very hot water as the design may develop small cracks.

Are you ready to get started?

Give us a call 435-628-9442 or request an online quote

Need Wholesale Printed Film Only?

Click HERE to go to our order portal and submit your order now.